Packwan

Date

19 Oct 2025

Duration

48 hours

Role

Team Lead

Track/Theme

Sustainability

Organizer

Design-a-thon (V-SIgn)

My Interpretation

The goal was to design eco-friendly, reusable or recyclable packaging that maintains usability, cost-effectiveness, and thermal/structural performance.

Key Constraints

Time: 48 hours

Limited prototyping resources (3D printing not feasible in time)

Tools: Research, 3D renders, ideation software, limited physical materials

All alone in Design Department with only one more team mate from B.TECH

Thought Process

Focused on holistic sustainability — material, packaging design, and system-level recycling. Prioritized research-driven material selection over quick prototyping.

Team Strategy

I handled material research, container design, and 3D renders

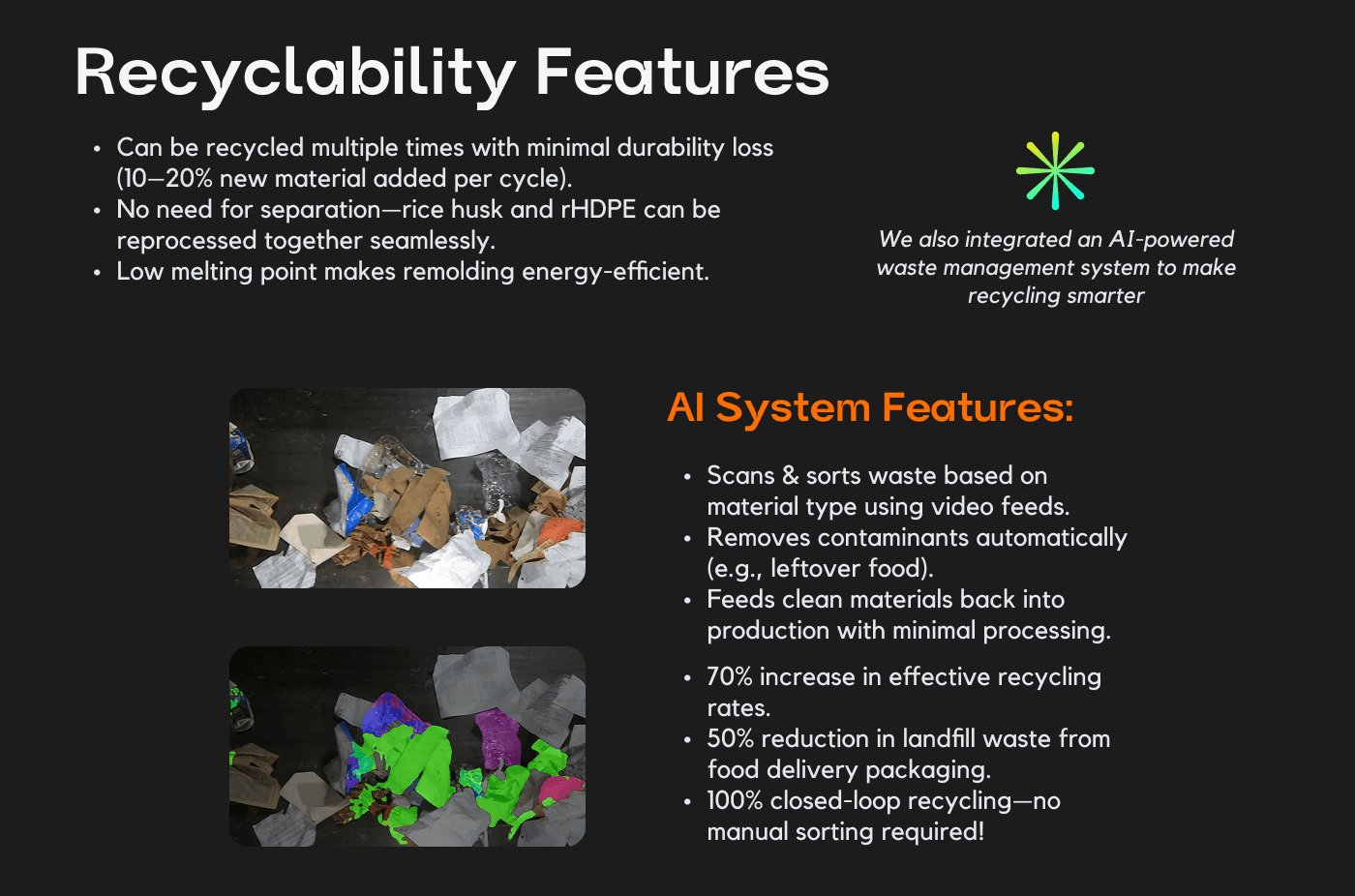

My friend (B.Tech CS) handled AI-driven waste recollection and circular system design

Decision Making

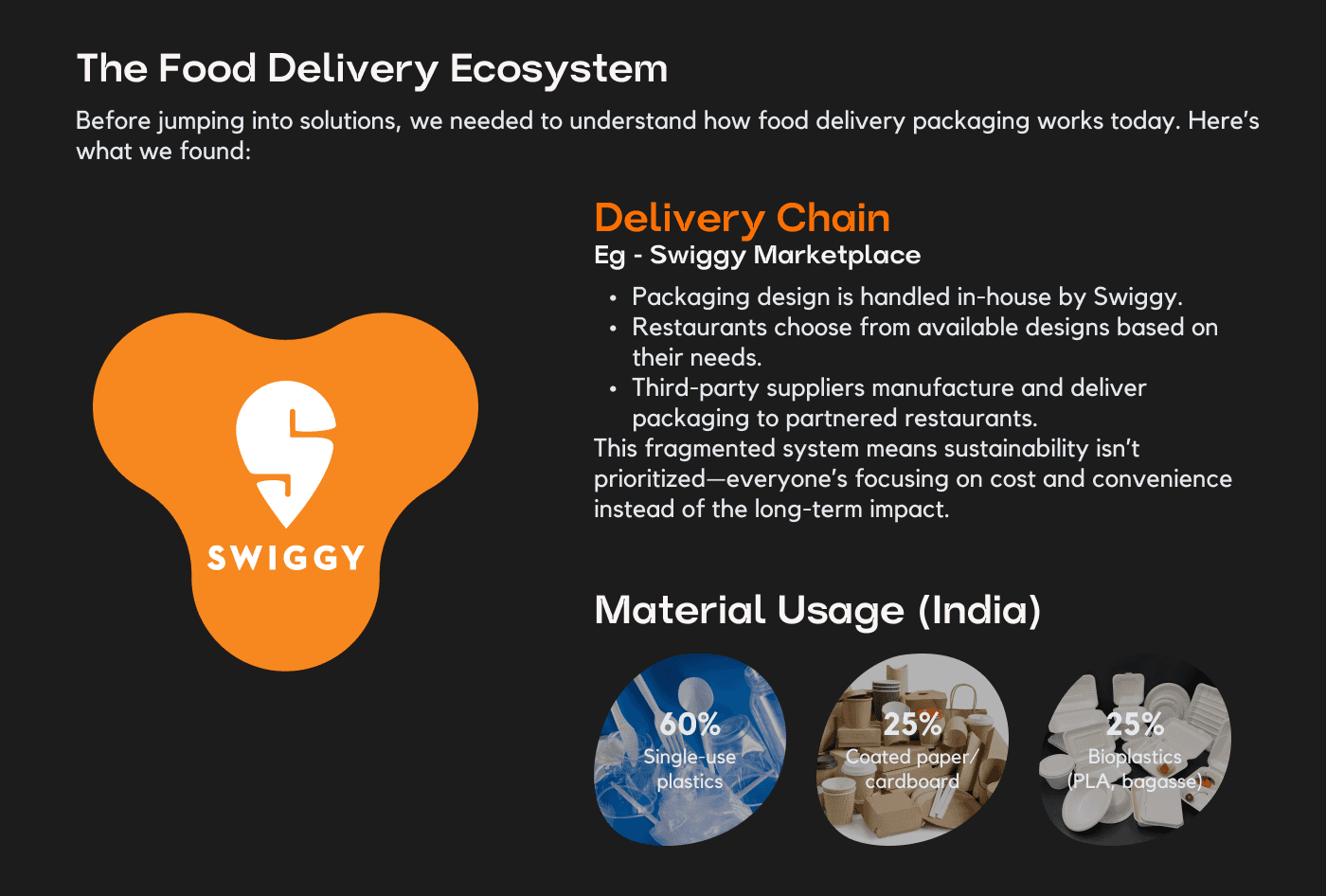

Quickly evaluated bamboo, PLA, bagasse → rejected due to cost, durability, or scalability issues

Settled on Rice Husk + rHDPE composite for affordability, recyclability, and thermal/mechanical performance

Solution Snapshot

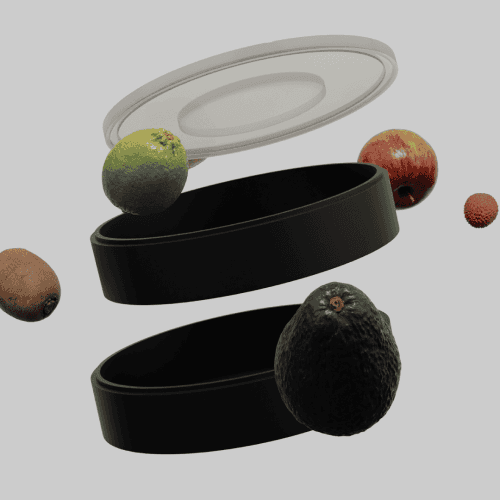

Developed a lightweight, recyclable food container using Rice Husk + rHDPE, paired with AI-powered waste recollection for a fully circular model.

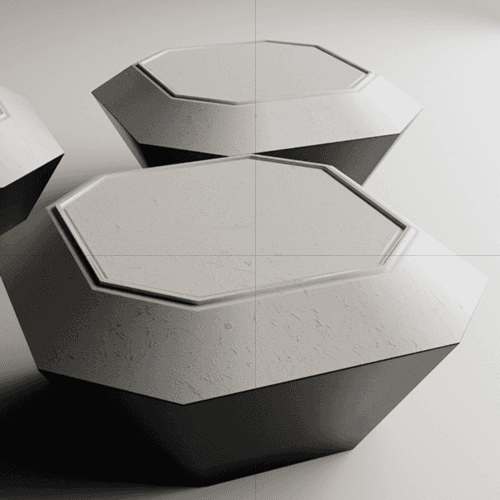

I modeled the entire packaging system in Blender, including container variations (200ml, 500ml, 1L).

Due to rendering constraints on my laptop, I traded off real-life 3D printing to prioritize a detailed animated product video that communicated usability and form.

Core Features

Rice Husk + rHDPE composite → strong, lightweight, heat-retaining, food-safe

Optimized container shapes → hexagonal, bento, tapered coffee mugs → minimal material use & stackable

Spill-proof & heat-retaining design → interlocking lids, curved interiors

AI-driven recycling system → smart sorting, QR-guided disposal, 80%+ recyclability

Scalable integration → B2B with Swiggy/Zomato

Results

We reached the finalist round, receiving jury appreciation for best overall idea and business scalability. The project demonstrated a viable alternative to current packaging with 60% lower environmental footprint and 80% recyclability potential.

Created a fully conceptualized, research-backed solution

Developed multiple 3D renders & teaser video

Learned cross-domain collaboration, rapid material analysis, and system-level sustainability design

What I’d Improve

Given more time, I would have prototyped physical models to test spill-proofing and thermal endurance, validating hypotheses from simulation.

Physical prototyping / 3D printing of containers

User testing with food delivery scenarios

Detailed AI implementation demonstration

Deep research yields better long-term impact than obvious solutions

Teamwork across disciplines → accelerated ideation and problem solving

Time constraints teach prioritization & trade-off management